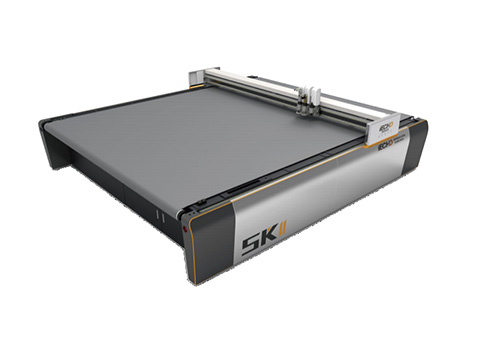

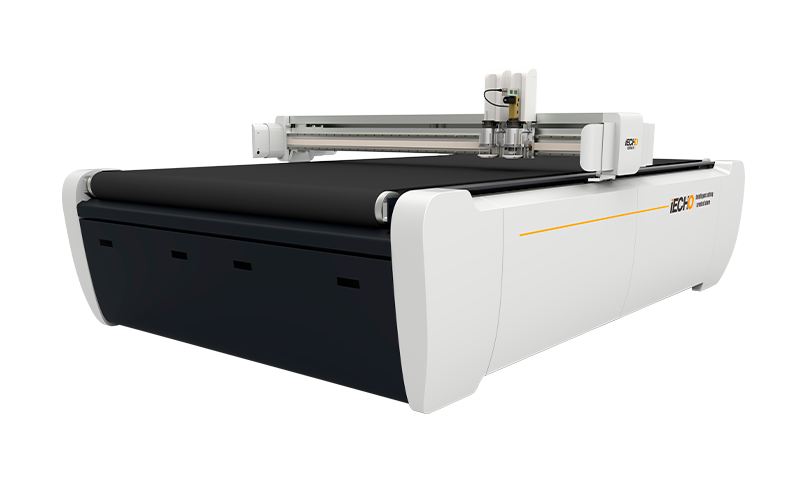

BK3

High-precision digital flatbed cutter for automated cutting, sampling, and short-run production workflows.

- Overview

- Product Support

The IECHO BK3 is a high-precision digital flatbed cutting system designed for efficient automated processing in signage, advertising print, and packaging environments. Optimized for sample making, short runs, and scalable production, the BK3 supports a wide range of processes including through cutting, kiss cutting, milling, punching, creasing, and marking. Integrated sheet feeding, conveyor transport, and collection tables enable a smooth, continuous workflow with minimal manual handling, making the system well suited for print service providers and converters looking to improve turnaround times and production consistency.

Engineered for speed and accuracy, the BK3 delivers cutting speeds of up to 1.5 m/s, significantly improving productivity compared to manual cutting methods. Its aviation-grade aluminum cutting table with zoned vacuum control ensures strong, energy-efficient material hold-down, while the intelligent conveyor system allows continuous cutting of long materials. Advanced features such as automatic knife initialization and CCD camera-based positioning enhance cutting depth control and registration accuracy, helping maintain reliable results even on printed or dimensionally sensitive materials. Overall, the BK3 provides a balanced solution that combines automation, precision, and flexibility in a compact flatbed cutting platform.