LCKS

High-efficiency digital leather and textile cutting solution with automated nesting and end-to-end workflow control.

- Overview

- Product Support

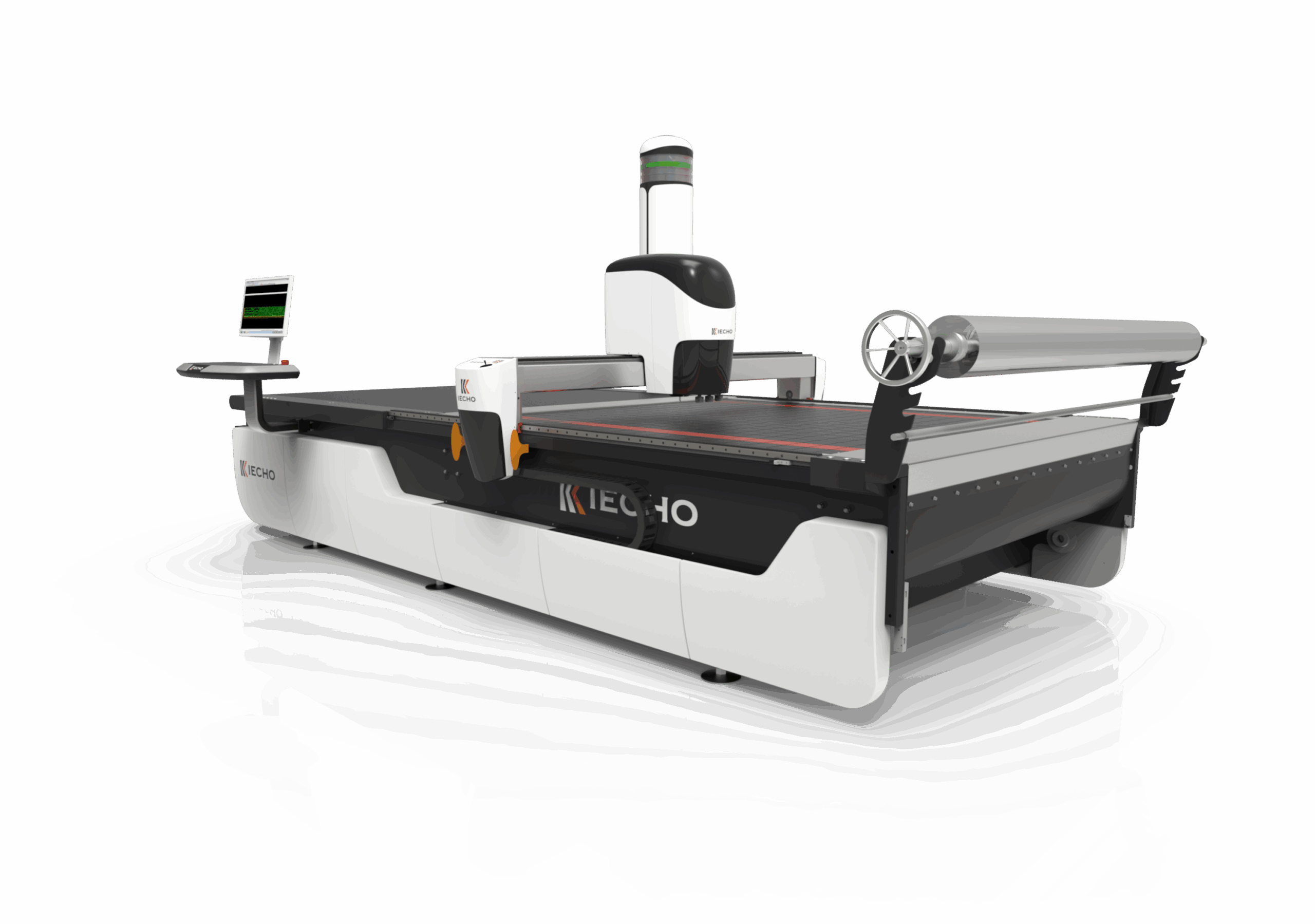

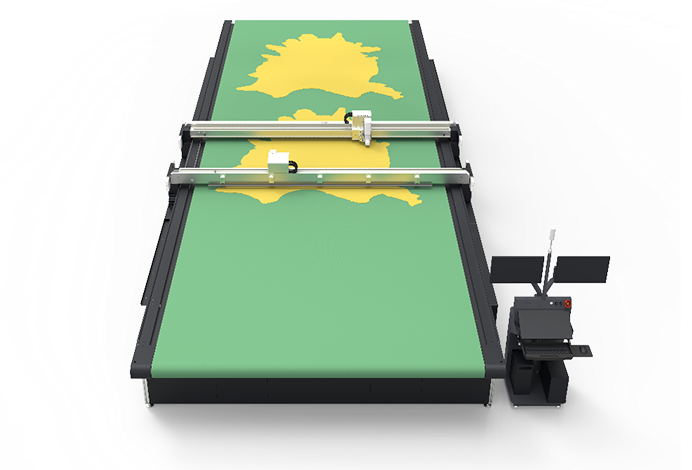

The IECHO LCKS is a fully digital, automated cutting and material management system engineered to streamline textile and leather cutting workflows for furniture, upholstery, automotive, footwear, and fashion applications. From high-speed contour collection and flaw recognition to precision nesting and automated cutting, the LCKS platform orchestrates each production stage with minimal manual intervention — enabling manufacturers to maintain tight control over quality and throughput while reducing reliance on skilled labor. At its core, the system integrates a digital order management interface, automatic nesting algorithms that maximize material utilization, and continuous assembly line processing to deliver faster order completion and a consistent cut quality across complex hide and textile shapes.

Designed as a complete digital cutting assembly line, the LCKS platform accelerates production with a three-stage workflow — scanning, nesting, and cutting — that can run continuously to improve operational efficiency dramatically. Equipped with high-contrast felt beds to secure materials and sensitive infrared safety sensors to protect operators and equipment, LCKS enhances both cutting precision and workplace safety. Its leather automatic nesting system completes full hide layouts in approximately 30–60 seconds, boosting material usage by an estimated 2–5% depending on defect grading and customer parameters, while real-time monitoring lets operators adjust jobs mid-process to maintain productivity and reduce waste.