PK4 1007

Automatic intelligent cutting system with CCD registration and versatile tool support for sample and short‑run production.

- Overview

- Product Support

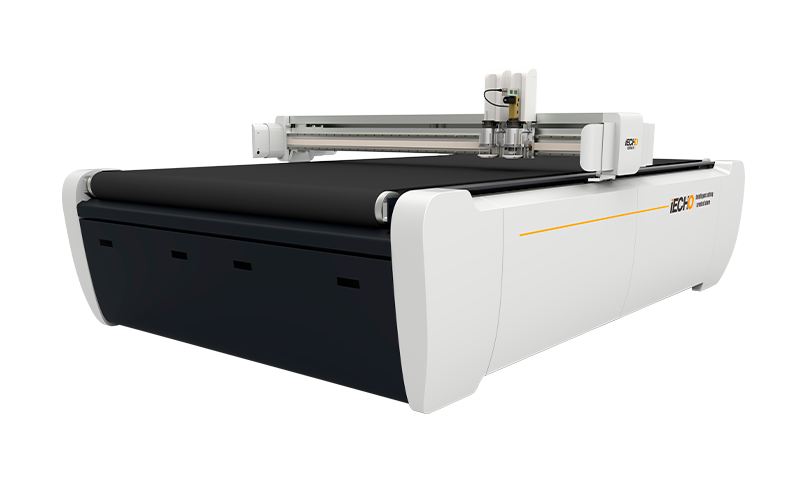

The IECHO PK4 Automatic Intelligent Cutting System is a smart, fully automated cutter designed to turn vector graphics into precise cutting paths with minimal manual intervention, making it ideal for sample making and short‑run customized production in signage, printing, and packaging industries. It combines an automatic sheet feeding and receiving setup with a high‑precision CCD vision registration system that ensures accurate contour alignment and continuous processing of printed materials. The PK4 accommodates a range of universal cutting tools — such as oscillating knives, creasing wheels, and EOT tools — to support functions like through cutting, kiss cutting, marking, and creasing across diverse substrates with reliable precision.

To enhance productivity and ease of use, the system also integrates automatic roll material feeding for vinyl and label stock, plus QR code scanning for quick retrieval of cutting jobs from the computer. With a maximum cutting speed of 1.2 m/s, machine operators benefit from faster throughput without sacrificing cut quality, and the PK4’s flexible tooling and intelligent control make it a cost‑effective solution for automated cutting workflows in creative and industrial settings.