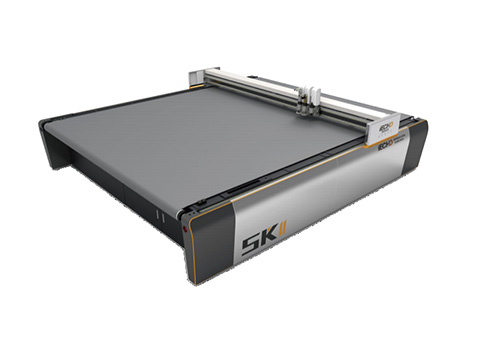

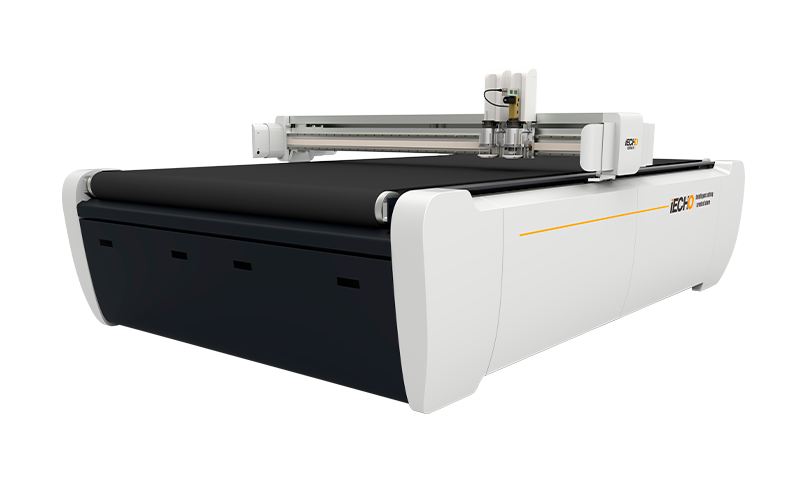

PK0604 / PK0705 Plus

Compact automatic intelligent cutter with CCD registration and versatile tooling for accurate, efficient material processing.

- Overview

- Product Support

The IECHO PK0604 / PK0705 Plus Automatic Intelligent Cutting System is a compact, fully automated digital cutting platform ideal for short‑run production, sample jobs, and customized finishing in signage, printing, packaging, and creative applications. These models convert vector graphics into precise cutting paths and use an automatic vacuum feeding and conveyor system to load, process, and collect sheets with minimal manual intervention. Built‑in CCD vision registration ensures accurate contour alignment of printed materials, removing the need for manual positioning and reducing operator setup time, while QR code scanning can be used to retrieve cutting files directly for continuous operation.

The standard PK0604 and PK0705 configurations support universal cutting tools, creasing wheels, and kiss‑cut tools for through cutting, half cutting, creasing, and marking on lighter substrates, with cutting areas of 600 × 400 mm and 750 × 530 mm respectively. The Plus variants add an oscillating cutting tool to extend material capability up to 6 mm thickness, expanding usable materials to include foam board, corrugated board, ABS, and more. Across the range, the systems offer reliable vacuum media hold, a vacuum stack feeder for unattended jobs, cutting accuracy of ±0.1 mm, and a maximum cutting speed of 1000 mm/s, giving a balanced blend of automation, versatility, and precision in a compact footprint.

Characteristics PK0604

Cutting Area(L*w)600mm x 400mm

Flooring Area(L*W*H)350mm x 900mm x 1150mm

Cutting TOOLUniversal Cutting Tool, Creasing Wheel, Kiss cut tool

Cutting MaterialCar sticker, Sticker, Card Paper, PP Paper, reflective material

Cutting Thickness<2mm

MediaVacuum System

Max Cutting Speed1000mm/s

Cutting Accuracy±0.1mm

Data FormalPLT, DXF, HPGL, PDF, EPS

Voltage220V±10%50HZ

Power4KW

Characteristics PK0705 Plus

Cutting Area(L*w)750mm x 530mm

Flooring Area(L*W*H)2350mm x 1000mm x 1150mm

Cutting TOOLOscillating tool, Universal Cutting Tool, Creasing Wheel, Kiss cut tool

Cutting MaterialKT Board, PP Paper, Foam Board, Sticker, Reflective Material, Card Board, Plastic Sheet, Corrugated Board, Grey Board, Corrugated Plastic, ABS Board, Magnetic Sticker

Cutting Thickness<6mm

MediaVacuum System

Max Cutting Speed1000mm/s

Cutting Accuracy±0.1mm

Data FormalPLT, DXF, HPGL, PDF, EPS

Voltage220V±10%50HZ

Power4KW

Request Quote

or call us on +30 210 238 9663